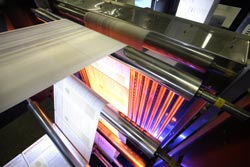

Heraeus Noblelight Strahler auf der DRUPA 2008

Carbon infrared emitters from Heraeus Noblelight allow high drying speeds to be achieved in the drying of personalised items of print. Carbon heaters can thus help significant savings in energy and operating costs to be achieved. Copyright Heraeus Noblelight 2007<br>

- Medium wave carbon infrared emitters dry water-based inks more efficiently

- Carbon emitters help to dry items of personalised printing at high speed

- Heraeus Noblelight is showing Carbon heaters for personalised digital printing at DRUPA

Carbon Infrared (CIR) emitters from Heraeus Noblelight dry ink jet printing inks especially efficiently. This is because medium wave infrared radiation is transferred into ink at high power. Above all, medium wave infrared radiation is absorbed very well by water-based inks. Consequently, carbon emitters can allow the printing of personalised mailings at high speed, saving energy and operating costs.

Carbon infrared heaters need nothing but the emitter operating in the near infrared region. There is no need for water cooling, allowing significantly reduced maintenance costs. The systems are easy to clean and need to be shut down less often. At DRUPA, Hall 3 Stand C35, Heraeus Noblelight will be showing Carbon infrared heaters for personalised digital printing in operation. Visitors will be able to see for themselves the fast response times of emitters.

Whether it be for publicity letters, brochure or direct mail shots, personalised digital printing is standard today. Essentially, pre-printed items are assembled as rolls or as individual sheets and then provided with the personalised printing in a given area. This personalised printing must be reliably and safely dried before the printed item can move to the next production stage, be this cutting, folding or gluing. The selection of the correct drier is not only vital for reasons of quality but also to ensure that the printing can be carried out at high speed. Medium wave emitters lend themselves especially to the drying of water-based inks. Infrared radiation in the medium wave region is that best absorbed by water. This helps to heat the ink in a focused manner, while, at the same time, treating the paper and the printing machine gently.

“Medium wave carbon infrared (CIR) emitters are particularly well suited as they combine effective medium wave lengths with high power and fast response times. Carbon emitters are fairly standard emitters in this segment” says Holger Zissing, Printing Applications Specialist at Heraeus Noblelight.

By using carbon emitters, which are precisely matched to the product and process, energy consumption can be significantly reduced. The Lettershop Group (TLG), one of Europe’s leading direct communications organisations, has already experienced this. TLG uses the latest web and sheet-fed technology to produce the highest quality direct mail print. Earlier, the drying process was carried out by using very high power, short wave infrared emitters, operating in the near infrared region. Since TLG converted to medium wave Carbon Infrared (CIR) for the drying process, they have been able to save around £30,000 per print line per year.

The new emitters require very little maintenance, as cleaning now takes only two to three hours compared with the two days of the short wave system. And after nearly two years, the first CIR emitters are still in full operation.

The new system also shows greater tolerance to sensitive papers, as the paper is heated only to around 30-35ºC, as opposed to the 60-70ºC of the short wave system.

Heraeus Noblelight GmbH with its headquarters in Hanau and with subsidiaries in the USA, Great Britain, France, China, Australia and Puerto Rico, is one of the technology- and market-leaders in the production of specialist light sources. In 2006, Heraeus Noblelight had an annual turnover of 88 Million € and employed 651 people worldwide. The organisation develops, manufactures and markets infrared and ultraviolet emitters for applications in industrial manufacture, environmental protection, medicine and cosmetics, research, development and analytical laboratories.

Heraeus, the precious metals and technology group headquartered in Hanau, Germany, is a global, private company in the business segments of precious metals, sensors, dental and medical products, quartz glass and specialty lighting sources. With revenues of more than EUR 10 billion and more than 11,000 employees in over 100 companies, Heraeus has stood out for more than 155 years as one of the world’s leading companies involved in precious metals and materials technology.

Further Information:

Readers:

Heraeus Noblelight GmbH

Reinhard-Heraeus-Ring 7

D-63801 Kleinostheim

phone +49 6181/35-8545, fax +49 6181/35-16 8545

E-Mail hng-infrared@heraeus.com

Press:

Dr. Marie-Luise Bopp

Heraeus Noblelight GmbH,

phone +49 6181/35-8547, fax +49 6181/35-16 8547

E-Mail marie-luise.bopp@heraeus.com

Media Contact

More Information:

http://www.heraeus-noblelight.comAll latest news from the category: Trade Fair News

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…