Wire laser material deposition – a smart way to save costs

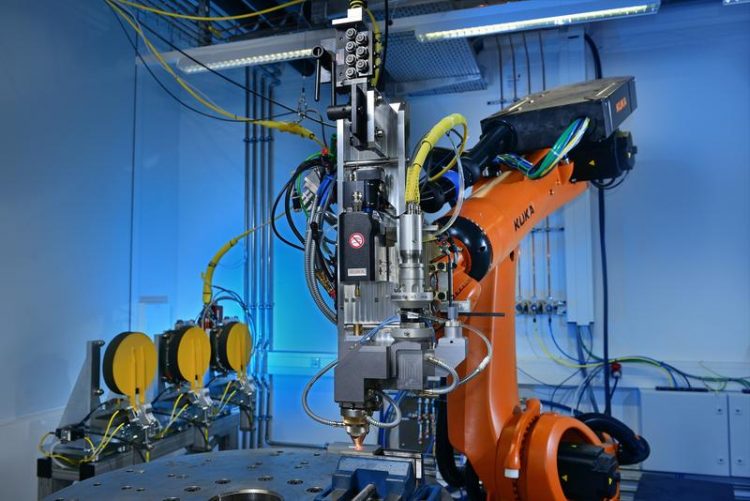

At formnext, Fraunhofer ILT will be showing a new processing head that enables wire LMD in hybrid processes as part of the BMBF's ProLMD project. © Fraunhofer ILT, Aachen, Germany

Production experts are increasingly facing a dilemma: Conventional manufacturing processes such as turning, milling, eroding or forming are gradually reaching their limits whenever large and complex, individual metal components need to be manufactured.

While additive manufacturing processes offer significant advantages in terms of saving raw materials, they still only have low deposition rates. Here, it makes sense to combine conventional and additive manufacturing processes.

Integrating hybrid production technology into existing systems

As part of the collaborative ProLMD project, funded by the German Federal Ministry of Education and Research (BMBF), Fraunhofer ILT is working with industrial partners to develop new processes for integrating hybrid laser material deposition (LMD) processes into the production chain. Their aim is to develop processes and systems that can be used, for example, to apply reinforcements or other geometric features onto cast or forged blank parts via LMD.

Developed at Fraunhofer ILT and now implemented in the ProLMD project, the new processing optics – with a ring-shaped beam – play an important role in coaxial LMD with wire. “The main advantage of the optics is the directional independence. Combined with the low cost filler material wire and a nearly 100 percent utilization, the overall costs can be reduced drastically”, explains Max Fabian Steiner, a researcher at Fraunhofer ILT. ”In addition, the process is dust-free. Compared to powder-based processes, it, therefore, not only offers cost savings but also improves occupational safety as well as environmental and employee protection”.

Working in high quality regardless of direction

The main features of the new processing optics are its directional independence and uniform intensity distribution of the laser beam intensity over the ring. Since reflective optics are used, such as copper in this case, high powers in a wide wavelength range are possible. Wire LMD can be used to manufacture components in a very high quality without pores and with extremely low post-processing requirements. In addition, the new head enables welding on 3D surfaces. As with most LMD processes, the new optics are equally suitable for repairing components.

By combining the non-directional process with a six-axis robot, the project partners have made the machining process very flexible. Since the application process can be controlled accurately, the process is stable even on large components and at high deposition rates, while maintaining consistent quality.

Inert gas cell enables titanium 3D printing

The new optics will be integrated into a process chain that improves the quality of the other components thanks to intermittent scanning. For this purpose, the geometry of the component is continuously recorded in order to adapt or correct the path planning with the aid of this data. An inert gas cell also allows users to repair titanium components in an argon atmosphere or to produce fully additive titanium components using 3D printing.

The experts from Fraunhofer ILT will be presenting the modular laser wire deposition head, the entire LMD process chain and the hybrid process at formnext from November 19 to 22 in Frankfurt am Main: at the joint Fraunhofer booth D51 in Hall 11.

The research and development project ProLMD is being funded by the German Federal Ministry of Education and Research (BMBF) under the grant number 02P15B115 as part of the ProMat3D funding measure. It is being supervised by the Project Management Agency Karlsruhe (PTKA).

Max Fabian Steiner M. Sc.

Group Laser Material Deposition

Telephone +49 241 8906-267

max.fabian.steiner@ilt.fraunhofer.de

Jan Bremer M. Sc.

Group Laser Material Deposition

Telephone +49 241 8906-356

jan.bremer@ilt.fraunhofer.de

Jana Kelbassa M. Sc.

Group Laser Material Deposition

Telephone +49 241 8906-8331

jana.kelbassa@ilt.fraunhofer.de

Media Contact

All latest news from the category: Trade Fair News

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…